Curing Lost Circulation

Solutions to manage your lost circulation challenges.

One of the principal functions of a primary cement job is to provide isolation between the various formation zones, including protecting water sources near surface. The most significant and perhaps most common risk to achieving this goal is failing to get cement returns to surface. The causes of lost circulation are generally naturally occurring spaces for fluid to flow through, such as porous rock, vugs and natural fractures. Additionally, they can be created through the drilling or cementing process by exceeding the fracturing gradient in some form and creating a fracture in which fluid can flow out of the annulus.

One of the principal functions of a primary cement job is to provide isolation between the various formation zones, including protecting water sources near surface. The most significant and perhaps most common risk to achieving this goal is failing to get cement returns to surface. The causes of lost circulation are generally naturally occurring spaces for fluid to flow through, such as porous rock, vugs and natural fractures. Additionally, they can be created through the drilling or cementing process by exceeding the fracturing gradient in some form and creating a fracture in which fluid can flow out of the annulus.

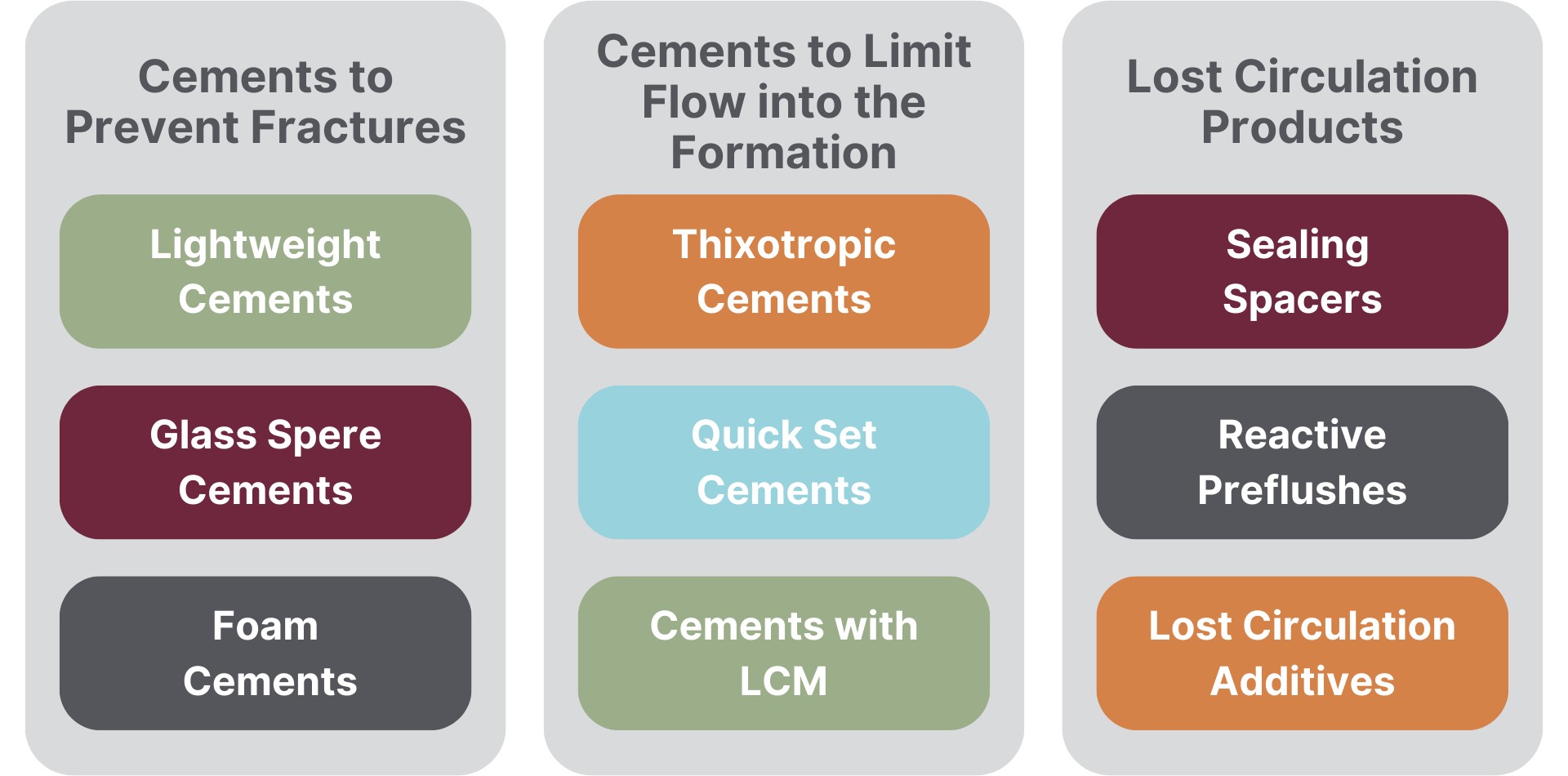

Sanjel Energy can identify the cause and severity of the losses to determine whether the well is safe to attempt cementing. Our cementing specialists match the best product to a predicted lost circulation concern, leveraging our historical job successes and failures in the geographic area to guide a successful cementing design. Our solutions include advanced cements to prevent fractures and limit flow

into the formation and novel lost circulation products.